If you are running a manufacturing plant, managing a complex fleet, or overseeing facility operations today, you likely feel a shift in the air. It’s not just the hum of the machinery or the daily grind of production schedules; it’s the pressure of a rapidly evolving industrial landscape.

As we look toward 2026, the conversation in boardrooms and on factory floors is no longer just about “fixing what’s broken.” It is about survival, operational intelligence, and the future of asset management.

The industry is facing a silent crisis. We are seeing a massive collision between aging infrastructure and the global demand for hyper-efficiency. The “old way”—paper checklists on clipboards, reactive fire-fighting, and fragmented spreadsheets—is no longer just inefficient; it is a liability that threatens the very existence of your business.

Here is what the industry is talking about right now, the specific challenges different sectors face, and why a Computerized Maintenance Management System (CMMS) is the pivot point between obsolescence and market dominance in 2026.

The “Silent Killer” of Profitability: The Reactive Trap

In late 2025 and moving into 2026, the biggest dilemma facing entrepreneurs and facility managers is the “Reactive Trap.”

You know the feeling: It’s 2:00 PM on a Tuesday. A critical conveyor belt snaps. The production line—the heartbeat of your revenue—flatlines. Your technicians are scrambling to find a spare motor that should be in inventory but isn’t. Every minute of downtime bleeds thousands of dollars, delays shipments, and damages your reputation with clients.

Business leaders are frantically searching for answers to “how to reduce unplanned downtime” because they are realizing a harsh truth: Reactive maintenance is only sustainable if you have an infinite budget. And in this economy, no one does.

The conversation has shifted. Maintenance is no longer a “cost center” to be minimized; it is a strategic competitive advantage to be optimized.

The “Silver Tsunami” and the Knowledge Gap

Compounding this dilemma is the skilled labor shortage. We are witnessing the “Silver Tsunami”—the mass retirement of Baby Boomers. These are the master technicians who knew a machine was about to fail just by the sound of its vibration.

When they walk out the door, decades of tribal knowledge leave with them. If your asset history lives entirely in the head of a technician named Bob who retires next month, your business is at immense risk. The new generation of “digital-native” workers needs data, not intuition, to keep your plant running.

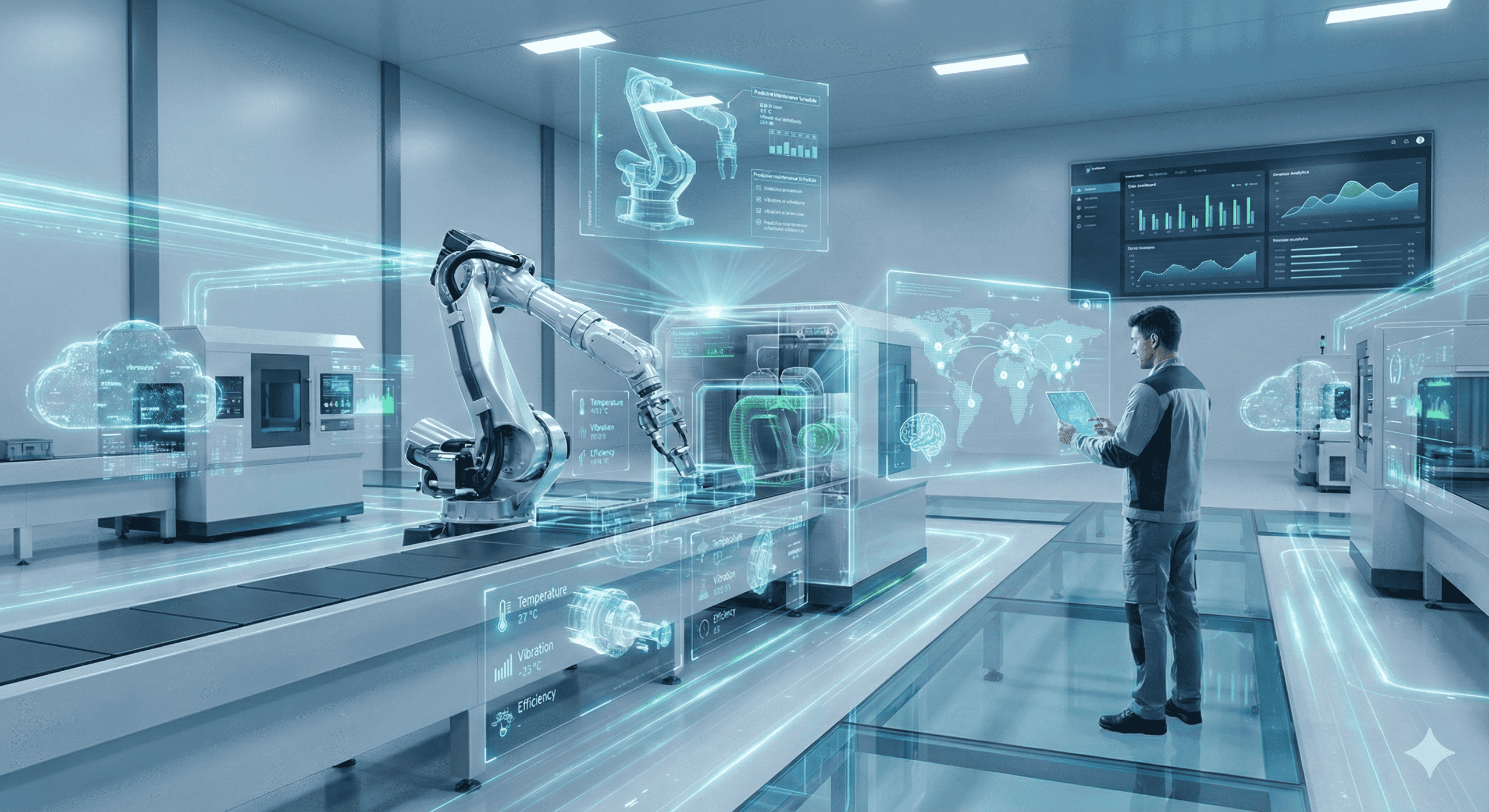

The 2026 Landscape: AI, IoT, and “Digital Labor”

As we approach 2026, we are witnessing the rise of Industry 5.0. This isn’t science fiction; it is the new standard. The buzzwords of the past—IoT (Internet of Things) and AI (Artificial Intelligence)—are becoming standard operating procedures for successful companies.

Here is what the future holds for your assets:

1. From Predictive to Prescriptive Maintenance

For years, everyone has been talking about predictive maintenance—using sensors to tell you when a bearing is vibrating too much. But 2026 takes it a step further to Prescriptive Maintenance.

Imagine a system that not only tells you something is about to break but acts on it.

The Scenario: A sensor detects a heat spike in an HVAC unit.

The Solution:The CMMS automatically triggers a work order, orders the specific replacement part from your vendor, and schedules the technician who has the highest rating for that specific repair. That is the power of automated maintenance workflows.

2. The “Digital Twin” Revolution

Manufacturing leaders are increasingly searching for “Digital Twin technology.”This involves creating a virtual replica of your physical assets.By feeding real-time data into a CMMS, you can simulate scenarios without risking your equipment.

What happens if we increase production speed by 10%?

Will the electrical grid handle the load of new machinery? A robust asset management tool answers these questions using data, not guesses.

3. Sustainability and “Green” Asset Management

The search volume for “sustainable manufacturing” and “ESG compliance tools” is skyrocketing. In 2026, your carbon footprint is as important as your throughput. Efficiently maintained machines use less energy.A CMMS helps you track energy spikes, prevent refrigerant leaks, and document compliance for environmental regulations. This makes your business not just profitable, but responsible—a key factor for modern investors and customers.

Industry Deep Dives: Who Needs This Technology Now?

The need for a CMMS isn’t limited to the factory floor. Here is how different industries are using this tech to solve 2026 problems:

🏥 Healthcare: Compliance is Queen

In healthcare, asset management is about patient safety. Hospitals are moving toward “Unified Asset Visibility.” With strict regulations from the Joint Commission and HIPAA, you cannot afford to lose track of equipment. A CMMS ensures that every ventilator, bed, and infusion pump is located, sanitized, and has a 100% audit-ready maintenance history.

🚚 Fleet & Logistics: The EV Transition

Fleet managers are wrestling with the transition to Electric Vehicles (EVs) and volatile supply chains. Maintaining a battery-electric powertrain is different from a diesel engine. Modern CMMS tools integrate with Telematics, feeding real-time odometer readings and fault codes into the system to trigger Just-in-Time maintenance, keeping trucks on the road and out of the shop.

🏢 Facility Management: The Hybrid Work Reality

Office buildings are no longer static; they are dynamic ecosystems. With hybrid work, usage patterns change daily. Facilities managers are using CMMS to switch from “Scheduled Maintenance” (cleaning every 4 hours) to “Usage-Based Maintenance” (cleaning only when sensors detect high foot traffic). This slashes labor costs and ensures a better tenant experience.

The Great Supply Chain Reset

If the last few years taught us anything, it’s that supply chains are fragile. Inventory management is no longer just about counting boxes; it’s about supply chain resilience.

Business owners are facing the challenge of “Ghost Inventory”—parts the system says you have, but physically don’t. Or worse, hoarding expensive parts you don’t need, tying up critical cash flow.

A top-tier CMMS solves this by:

Optimizing Stock Levels: Using historical data to predict exactly what parts you need for the upcoming season.

Automated Reordering: Setting minimum quantity thresholds so the system orders parts before you run out.

Vendor Management: Tracking which vendors deliver on time and which ones cause delays.

Why MicroMain is the Architect of Your 2026 Strategy

This is where the rubber meets the road. You don’t need another complex piece of software that takes a PhD to operate. You need a tool that bridges the gap between the human workforce and the digital future.

At MicroMain, we have been listening to the industry. We know that the entrepreneurs of tomorrow need:

Mobility First: Technicians need the power of the CMMS in their pockets. Mobile work order management is non-negotiable for a generation that grew up on smartphones. They need to snap pictures of repairs, scan barcodes, and close tickets from the field.

User-Friendly Interfaces: If your team can’t use it, they won’t. We prioritize “humanized” software design that simplifies complex data into actionable insights.

Data-Driven ROI: You need to prove to your stakeholders that every dollar spent on maintenance returns two dollars in reliability. Our reporting tools make that easy.

Future-Proofing Your Enterprise

The trends for 2026 are clear: Automation, Data Independence, and Proactive Strategy.

Don’t let your business be a statistic of the “Reactive Trap.” The dilemma of the modern manufacturer is solvable, but it requires the right tools. Whether you are in healthcare, manufacturing, hospitality, or fleet management, the thread that ties success together is reliability.

The future isn’t just coming; it’s already here, waiting for you to log in.

Ready to lead your industry in 2026?

Stop reacting to problems and start predicting success.

Discover how MicroMain can transform your operations today at www.micromain.com