The Industrial Renaissance of 2025: A Comprehensive Analysis of Manufacturing Transformation

Executive Summary: The Convergence of Intelligence, Resilience, and Human Potential

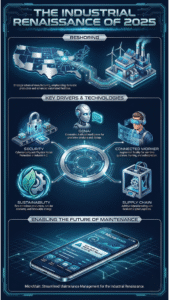

The global manufacturing sector in 2025 stands at a pivotal historical juncture, characterized by a simultaneous convergence of geopolitical restructuring, unprecedented technological acceleration, and a fundamental reimagining of the human role in production. We are no longer merely in the era of “Industry 4.0,” which emphasized connectivity and data collection; the industry has aggressively pivoted toward an era defined by cognitive agency, resilience, and sustainability—often termed Industry 5.0. This report provides an exhaustive analysis of the current state of manufacturing, specifically tailored to provide strategic depth for Computerized Maintenance Management System (CMMS) and Enterprise Asset Management (EAM) providers.

The landscape is dominated by five interconnected “buzz” topics that are reshaping the factory floor:

Generative AI and the “Cognitive Factory”: Moving beyond predictive analytics, Generative AI (GenAI) is now acting as an industrial copilot, drafting work orders, synthesizing repair manuals, and essentially “healing” operational workflows through autonomous decision-making.

The Augmented Connected Worker: In response to the labor shortage, manufacturers are deploying Augmented Reality (AR) and connected worker platforms to rapidly upskill a new generation, turning the CMMS into a knowledge transfer engine.

Strategic Reshoring and the “Genesis Mission”: Driven by national security imperatives like the U.S. “Genesis Mission,” supply chains are contracting and localizing. This shift demands hyper-efficient, automated domestic facilities where asset reliability is the only hedge against higher labor costs.

Sustainability as Operational Strategy (ESG 2.0): Energy efficiency and carbon reporting have transitioned from corporate social responsibility (CSR) initiatives to hard operational metrics, with predictive maintenance serving as a primary lever for decarbonization.

The Cyber-Physical Battlefield: As Operational Technology (OT) converges with Information Technology (IT), the factory floor has become a primary target for ransomware, necessitating a “Zero Trust” security architecture embedded within maintenance protocols.

For a CMMS provider, these trends are not merely external market forces; they represent the evolving feature set and value proposition required to remain competitive. The CMMS is evolving from a system of record into the central operating system of the resilient, sustainable, and cognitive factory.

1. The Macro-Industrial Landscape of 2025

To understand the specific technological and operational shifts occurring on the factory floor, one must first contextualize them within the broader macroeconomic and geopolitical environment of 2025. The manufacturing sector is currently operating under intense pressure, acting as the fulcrum for national economic security strategies and global trade realignment.

1.1 The “Genesis Mission” and the Return of Industrial Policy

In late 2025, the manufacturing world was galvanized by the United States government’s launch of the “Genesis Mission.” This executive order represents a historic national mobilization, explicitly compared in scope and ambition to the Manhattan Project. Unlike previous industrial policies that relied on indirect incentives, the Genesis Mission is a direct, coordinated effort to secure American dominance in critical technologies, specifically Artificial Intelligence (AI) and advanced manufacturing.

The implications for the manufacturing sector are profound. The federal government is no longer a passive regulator but an active partner and investor. The Department of Energy (DOE) is leading efforts to integrate AI into scientific discovery and industrial production. For manufacturers, this creates a dual-edged environment: there is unprecedented funding and support for innovation, particularly in AI-enabled workflows, but there is also intense pressure to modernize. Facilities that rely on legacy systems and outdated maintenance practices risk being locked out of this new industrial ecosystem.

1.2 The Economic Imperative: Reshoring in a High-Cost Environment

The geopolitical fracturing of the early 2020s has solidified into a permanent restructuring of global supply chains. The era of efficiency-at-all-costs, driven by cheap labor in distant markets, has ended. In its place is the era of resilience. “Reshoring”—bringing manufacturing back to the domestic US—and “Nearshoring” are the dominant strategies for 2025.

However, this strategic shift collides with a stark economic reality: the cost of production in North America remains significantly higher than in the Asian manufacturing hubs of the past decades. The “2025 Reshoring Index” highlights a “great reality check,” noting that while CEO commitment to reshoring is at an all-time high, the domestic manufacturing ecosystem faces structural cost challenges.

Table 1: The Reshoring Equation

| Factor | Offshore Model (Historic) | Reshore Model (2025) | Implication for Maintenance |

| Labor Cost | Low; manual processes feasible | High; requires automation | Reliability of automation assets is critical to justify ROI. |

| Supply Chain | Long, lean, fragile (JIT) | Short, robust, buffered (JIC) | Inventory management in CMMS must account for strategic buffering. |

| Energy | Often subsidized | Market rates; green focus | Energy efficiency becomes a direct driver of profitability. |

| Asset Age | Often newer purpose-built plants | Aging domestic brownfields | Maintenance must extend the life of older US assets. |

This economic equation places an immense burden on operational efficiency. A factory in Ohio cannot afford the same downtime or waste as a factory in a low-cost region. Every minute of machine uptime must be maximized to offset the higher labor and operational overheads.

1.3 The Aging Infrastructure Challenge

Compounding the reshoring challenge is the physical state of the U.S. industrial base. The average age of industrial equipment in the United States has been steadily climbing. Data from the Bureau of Economic Analysis indicates that private fixed assets in industrial equipment have continued to age, with many facilities operating machinery that is decades old. The average age of construction equipment, for instance, hovers around 9 years.

This “brownfield” reality means that most manufacturers are not building new smart factories from scratch; they are retrofitting intelligence onto legacy iron. This environment is the primary battleground for CMMS. The challenge is not just maintaining new robots, but predicting failures in 30-year-old stamping presses using modern IoT sensors.

2. The Technological Renaissance: Generative AI and the Cognitive Factory

If the Genesis Mission provides the political fuel, Generative AI (GenAI) provides the engine for the 2025 industrial transformation. The buzz surrounding AI in manufacturing has shifted from “Predictive” (telling you something might break) to “Generative” and “Agentic” (telling you how to fix it, or fixing it autonomously).

2.1 From Analytical to Generative Intelligence

For the past decade, Industry 4.0 focused on Analytical AI—machine learning models that ingested sensor data to identify patterns indicative of failure. While effective, this approach hit a plateau: it created alerts, but it didn’t create solutions.

In 2025, GenAI has shattered this barrier. By leveraging Large Language Models (LLMs) trained on vast repositories of technical documentation, maintenance logs, and sensor data, GenAI can now synthesize information to perform complex cognitive tasks.

Table 2: Evolution of AI in Maintenance

| Stage | Capability | Outcome | Role of CMMS |

| Reactive | “It broke.” | Fix it. | Log the repair. |

| Preventive | “It might break soon.” | Schedule maintenance. | Schedule calendar-based tasks. |

| Predictive | “Vibration is high.” | Investigate the asset. | Ingest sensor alerts. |

| Generative | “Bearing #4 is failing. Here is the SOP.” | Execute the repair. | Generate the work order and guide the tech. |

2.2 The Rise of the “Industrial Copilot”

The most visible application of GenAI in 2025 is the “Industrial Copilot.” These are conversational interfaces embedded within maintenance software that allow technicians to interact with their machinery and data using natural language.

Companies like Google Cloud and Siemens have rolled out specific GenAI solutions for manufacturing that enable this exact workflow.

Siemens Industrial Copilot: Unveiled at CES 2025, this tool brings AI directly to the shop floor, allowing operators to ask complex questions about machine status and receive instant, technically accurate answers.

Google Cloud: Uses Retrieval-Augmented Generation (RAG) to pull data from proprietary PDF manuals and operator notes, creating “Data Agents” that help solve problems in real-time.

2.3 Mechanisms of Action: How GenAI Transforms Maintenance

The integration of GenAI into CMMS fundamentally alters three core maintenance workflows:

1. Automated Work Order Generation:

GenAI systems can ingest unstructured data—an email from an operator or a raw sensor log—and structure it into a complete work order. It populates fields for asset ID, priority, required parts, and safety procedures automatically. This reduces the administrative burden on maintenance planners.

2. Dynamic Standard Operating Procedures (SOPs):

Static PDF manuals are obsolete. GenAI can generate dynamic, context-aware SOPs. If a technician is repairing a machine in a high-temperature environment, the AI generates safety instructions specific to that condition.

3. Root Cause Analysis (RCA):

When a breakdown occurs, GenAI can instantly perform a preliminary Root Cause Analysis by correlating the failure with historical events. It might notice that “Pump A fails every time Valve B is closed too quickly,” a correlation that might escape a human reviewer looking at isolated incidents.

2.4 Case Studies in GenAI Adoption

The impact of this technology is measurable and significant across the industry.

Georgia-Pacific: This manufacturing giant utilized GenAI services to capture the tribal knowledge of experienced operators. They built a chatbot that allows new employees to query the collective wisdom of the organization, significantly accelerating onboarding and reducing machine downtime caused by operator error.

Bosch: In their German factories, Bosch implemented GenAI to replace manual inspection of fuel injection components. The AI generates synthetic images of defects to train its detection models, reducing the time to launch new AI applications from months to weeks.

Toyota: By leveraging predictive capabilities and intelligent systems, leading organizations like Toyota now complete 89% of maintenance tasks before failures occur, a shift that is saving billions in avoided outages.

2.5 The Hallucination Challenge and Data Integrity

Despite these advances, the adoption of GenAI is not without risk. The primary challenge is “hallucination”—where the AI confidently provides incorrect information. In a manufacturing setting, a hallucinated torque specification could be fatal. This risk elevates the role of the CMMS to that of a “source of truth.” For GenAI to be safe, it must be grounded in accurate, curated data.

3. The Human Crisis: Bridging the Labor Gap with “Connected Worker” Technology

While AI provides the cognitive power, the physical execution of manufacturing still relies on human hands. However, the industry is facing a demographic crisis of existential proportions, often referred to as the “Silver Tsunami.”

3.1 The Demographics of a Crisis

By 2030, the U.S. manufacturing sector is projected to have over 2 million unfilled jobs. In 2025, this shortage is acutely felt in skilled trades—welders, machinists, and maintenance technicians. When a 30-year veteran technician retires, they take with them an intuitive understanding of the plant’s idiosyncrasies that are rarely documented.

Simultaneously, attracting younger workers to manufacturing remains difficult. 72% of manufacturers believe outdated technology prevents them from attracting new talent. The younger workforce is digital-native; they expect the same level of technological sophistication at work as they have in their personal lives.

3.2 The Solution: Augmented Connected Worker (ACW) Platforms

To bridge this gap, the industry is turning to “Connected Worker” technology. This sector involves software and hardware that integrates the frontline worker into the digital ecosystem. It is one of the fastest-growing categories in industrial software, with platforms like Augmentir and Poka leading the market.

Mechanism of Action:

These platforms function by delivering the right information to the right worker at the right time, usually via mobile tablets, smart glasses, or wearables.

Digital Work Instructions: Instead of a binder, a technician receives a step-by-step digital guide for a repair task.

Remote Expert Guidance: Utilizing Augmented Reality (AR), a junior technician on the shop floor can initiate a video call with a senior expert located anywhere in the world. The expert can see what the technician sees and digitally “draw” on the screen to guide them.

Table 3: Top Connected Worker Use Cases

| Use Case | Description | Benefit |

| Onboarding | Interactive, AR-based training modules. | Reduces time-to-productivity for new hires. |

| Safety Monitoring | Wearables that track worker location and hazards. | Reduces incident rates. |

| Knowledge Capture | Tools for technicians to record videos of repairs. | Preserves tribal knowledge before retirement. |

| Collaborative Ops | “Social media” style feeds for factory floors. | Improves shift handovers. |

4. Supply Chain Resilience: From “Just-in-Time” to “Just-in-Case”

The disruptions of the early 2020s have permanently altered supply chain philosophy. The fragile efficiency of “Just-in-Time” (JIT) manufacturing has been exposed as a liability. In 2025, the dominant strategy is “Just-in-Case” (JIC) or “Resilience-First.”

4.1 The Role of Maintenance in Supply Chain Stability

Maintenance is no longer just about fixing machines; it is about securing the supply chain. In a constrained global market, the ability to predict spare parts consumption is a competitive advantage. If a critical component requires a replacement part with a long lead time, a reactive failure is catastrophic.

Predictive Parts Management:

Modern maintenance platforms are integrating with supplier systems to provide “Predictive Inventory Management.” Instead of relying on static stock levels, these systems use AI to forecast parts usage based on asset health. This reduces “parts anxiety” while ensuring critical spares are available.

4.2 3D Printing and the Digital Spare Parts Warehouse

A key technology enabling this resilience is Additive Manufacturing (3D Printing). In 2025, manufacturers are increasingly maintaining “Digital Warehouses”—repositories of CAD files for spare parts rather than physical shelves.

Anycubic at Formnext 2025: New breakthroughs in desktop manufacturing have brought industrial precision to small-batch production. Printers introduced in late 2025 allow for multi-material printing, enabling the on-demand production of complex parts directly on the shop floor.

5. Sustainability as Operational Strategy: ESG 2.0

Sustainability has evolved from a marketing buzzword to a rigorous operational discipline. In 2025, “Green Manufacturing” is driven by two powerful forces: regulatory compliance and energy cost management.

5.1 The Regulatory Vise: CSRD and SEC

New reporting frameworks like the European Union’s Corporate Sustainability Reporting Directive (CSRD) have made Environmental, Social, and Governance (ESG) reporting mandatory for major manufacturers. These regulations require detailed data on Scope 1, 2, and 3 emissions. This transforms maintenance logs into a compliance engine, providing the primary data for emissions calculations.

5.2 Reliability is Sustainability

The most significant insight in 2025 is the direct correlation between Asset Reliability and Energy Efficiency. A degraded asset is an energy hog.

Friction & Heat: A gearbox with contaminated oil generates excess heat, requiring more energy.

Start/Stop Cycles: Unplanned downtime forces machines to shut down and restart—a process that consumes massive surges of energy compared to steady-state operation.

Case studies show that implementing predictive maintenance to optimize asset health can reduce overall energy consumption by up to 15-20%. For energy-intensive industries, this represents millions of dollars in direct savings, fundamentally altering the ROI calculation for maintenance software.

6. The Cyber-Physical Threat Landscape: Security in the OT Era

As factories become more connected, they become more vulnerable. The convergence of Operational Technology (OT)—robots, PLCs, conveyors—with Information Technology (IT) has created a massive, often poorly defended attack surface.

6.1 The Rise of Ransomware in Manufacturing

In 2025, manufacturing was the most targeted sector for cyberattacks for the third consecutive year. Criminals target manufacturers because they have a low tolerance for downtime.

Incident Profile: In May 2025, Nucor, North America’s largest steel producer, detected unauthorized access and halted production at multiple sites as a precaution. This highlights the physical and financial catastrophe of cyber incidents.

6.2 The “Zero Trust” Solution

The solution dominating 2025 is “Zero Trust” architecture. This security model assumes that no user or device is trusted, even if they are inside the network perimeter.

For maintenance providers, this means:

Role-Based Access Control (RBAC): Ensuring a junior tech cannot alter critical system configurations.

Cloud Security: Leveraging the robust security of cloud providers is now seen as more secure than on-premise servers, which are often poorly patched.

7. Insights from the Global Stage: 2025 Convention Highlights

The direction of the industry is most vividly displayed at the major global trade shows.

7.1 CES 2025: The Industrial Metaverse

Once a consumer electronics show, CES has transformed into a major industrial technology hub. In 2025, the focus was the “Industrial Metaverse.”

Siemens & NVIDIA: These giants showcased “Physically Based Visualization” systems. This allows manufacturers to build photorealistic Digital Twins of their factories to optimize flow and debug code before physical implementation.

7.2 Hannover Messe 2025: Data Ecosystems

The world’s largest industrial fair focused on “Digital Ecosystems.”

AI Everywhere: The number one topic was AI applications for industry. The consensus is that AI has the potential to change industry more in a few years than in the entire past decade.

Partner Country Canada: Highlighted the integration of AI and hydrogen technology, emphasizing the global push for sustainable energy sources.

7.3 IMTS 2024/2025: Automation for All

The International Manufacturing Technology Show (IMTS) highlighted the democratization of automation.

SME Automation: The show floor featured affordable automation solutions for small to medium-sized manufacturers, signaling that advanced maintenance needs are no longer exclusive to the Fortune 500.

Scan-to-Path: New tech that allows a robot to scan a part and automatically generate the path for sanding or painting, eliminating hours of programming time.

8. Strategic Alignment: Where MicroMain CMMS Serves the Future Factory

In the context of these shifting industrial paradigms, MicroMain CMMS acts as a critical enabler for manufacturers attempting to bridge the gap between legacy infrastructure and the modern cognitive factory. By addressing the core challenges of 2025—workforce mobility, predictive reliability, and data security—MicroMain positions itself not just as a tracking tool, but as a strategic asset for operational resilience.

8.1 Empowering the “Connected Worker”

As the industry faces the “Silver Tsunami” and a shortage of skilled labor, the user experience of maintenance software becomes a primary tool for retention and efficiency. MicroMain addresses this via a mobile-first architecture designed to support the “Connected Worker.”

Seamless Tracking: The system utilizes QR codes and barcode scanning to instantly link technicians to asset history and work orders on the shop floor, eliminating paper trails and reducing administrative time.

Mobile Accessibility: By providing full CMMS functionality on mobile devices, MicroMain allows technicians to access manuals, update statuses, and check inventory remotely. This directly supports the 2025 trend of untethering workers from desktop terminals, increasing “wrench time” and data accuracy.

8.2 Securing the Cyber-Physical Interface

With manufacturing becoming the top target for ransomware, the security of the CMMS is paramount. MicroMain distinguishes itself with Robust Security Features that align with “Zero Trust” principles.

Role-Based Access Control (RBAC): MicroMain employs granular permission settings, ensuring that users only access data relevant to their specific roles. This minimizes the internal attack surface and prevents unauthorized changes to critical asset configurations.

Data Protection: As a cloud-based solution, MicroMain leverages enterprise-grade security protocols, offering a higher level of data protection than many legacy on-premise systems that struggle with patch management.

8.3 Facilitating the Transition to Industry 4.0 and 5.0

MicroMain serves as a foundational layer for the transition from reactive to predictive and prescriptive maintenance models.

Predictive Maintenance Readiness: The platform is designed to integrate with Industry 4.0 technologies, including IoT sensors and AI-driven analytics. By centralizing data from these sources, MicroMain enables the shift from calendar-based maintenance to condition-based strategies, which can reduce downtime by significant margins.

Sustainability and ESG Compliance: By extending the life of equipment through rigorous preventive maintenance scheduling, MicroMain directly contributes to the “Circular Economy” goals of reducing waste and capital expenditure. Furthermore, its reporting capabilities provide the data necessary for Scope 1 and 2 emissions tracking, a critical requirement for ESG compliance in 2025.

8.4 Economic Impact and ROI

In an era defined by high-cost reshoring, the ROI of maintenance software is scrutinized heavily. MicroMain’s focus on “Operational Efficiency” delivers measurable financial outcomes that justify the investment.

Cost Reduction: Industry research indicates that implementing a system like MicroMain can reduce overall maintenance costs by up to 70% and increase asset life by 10%.

Inventory Optimization: The system’s parts management features prevent both stockouts (which cause downtime) and overstocking (which ties up capital), addressing the “Just-in-Case” supply chain challenges of the modern era.

Conclusion

The manufacturing industry of 2025 is a study in contrasts: it is high-tech yet labor-constrained; it is globalized yet rapidly localizing; it is digital yet heavily reliant on aging physical infrastructure.

The winners in this new era will be the manufacturers who successfully navigate these contradictions. They will be the ones who use Generative AI not to replace workers, but to give them superpowers. They will use Reshoring not just as a political slogan, but as a catalyst for automation and efficiency. They will view Sustainability not as a tax, but as a method to reduce waste and energy costs.

For CMMS and EAM providers like MicroMain, the mandate is clear: build tools that are intelligent, intuitive, and secure. The maintenance platform is the bridge between the human technician and the cognitive factory. By strengthening this bridge, the industry secures not just the machinery but the future of production itself.